CONFORMAL COATING

Processing machines for efficient coating of printed circuit boards

Are you looking for a modern conformal coating platform for sustainable protection of printed circuit boards? You too can benefit from the very best engineering and manufacturing expertise right across the board. Whether simple desk-top unit or integrated coating line, the parameters for a modern coating platform and processing unit extend from the required quantity via drying times to run-time calculation.

WERNER WIRTH is used to thinking in terms of the bigger picture while not forgetting the smallest detail and still saving a few minutes at some point along the way. For example, with multiple valves in four-axis systems (e.g. for dam and fill), combining several work steps or recommending a different coating material.

Benefit from our comprehensive range and know-how. Also including valve technology and accessories.

Made for efficient production

From stand-alone to complete production lines

- Plug and Play

- For many coating and dosing applications

- Simple and intuitive operations

- High precision, quality and repeatability

- Individual planning and sound advice included

Conformal coating processing machines

PROTECTIONAll you need for printed circuit board protection: from manual desktop systems to integrated coating lines

Every type of component protection needs its own production machinery that is a perfect match. Together we find and implement the solution that is ideal for you in every respect. This will often be the Alpha 6, our all-rounder: planned to individual requirements from the standalone solution to the integrated coating line with robust drive system, with optional features such as up to 6 axes, belt transport system with automatic width adjustment, camera system, machine lighting with black light, MES integration and many other extras.

Needless to say we also supply board handling systems, drying lines and inspection systems all from a single source. So you see, we like to think with and for you. After all, good business relations are not a one-way street. Just talk to us about it! We’ll be glad to help.

Processing platforms

The perfectly matching coating machine including individual planning and sound advice

Meet the Alpha 6 by WERNER WIRTH: the innovative, compact processing platform that is extremely easy to use for many different coating and dosing applications. See for yourself, preferably live, how the system stands out with high precision and coating quality, reproducibility in application and amazing flexibility when it comes to meeting many different requirements.

The all-rounder

The WW Alpha 6 by WERNER WIRTH is an innovative, compact processing platform for a wide range of coating and dosing applications. It stands out with simple, intuitive operation. It is also extremely flexible in meeting many different requirements.

The machine is designed as a self-contained working cell that can be used for coating and dosing various media. It can also be used for other customer-specific applications, such as treatment with atmospheric plasma, for example. WW Alpha 6 is a robust, aesthetically pleasing machine that stands for high precision, quality and reproducibility in application.

Automatic continuous loading of the production line from the storage rack. The loader pushes printed circuit boards straight out of the storage rack onto the downstream transport module towards the production line.

Transports printed circuit boards between the individual process machines in the production line. Flexible configuration of the production line thanks to different process lengths.

Transports printed circuit boards between the individual process machines in the production line. Flexible configuration of the production line thanks to different process lengths.

Modular inline UV curing system with 4 safety locks. The UV Cure picks the printed circuit boards up with a 3-zone transport system and brings the products into the UV tunnel. Here the products being cured are exposed to UV light and stabilised in a few seconds.

Automatic continuous unloading of the production line from the stack. The unloader takes the printed circuit boards out of the production line and pushes them into the storage rack. The storage rack is changed automatically depending on how full it is.

Valve technology

Valves for spraying, film-coating, jetting and dispersing

WERNER WIRTH offers precision technology on the very highest standard, also and particularly when it comes to valve technology. We offer best valve technology for every application: coating, dispensing, bonding and potting.

Whether film coat valves, jet valves, dispensing valves or spray valves, we have all you need for perfectly dosed, reliable component protection in highly sensitive electronic applications subject to extreme conditions.

Please do not hesitate to contact us if you have any further questions.

Musashi valves

We use and recommend valves by Musashi: film coat valves for high speed coating, contact-free high precision jet valves or also spray valves for universal applications. This warrants the high coating quality and reproducibility of our WW Alpha 6 “all-rounder”, while being extremely easy to use and absolutely robust.

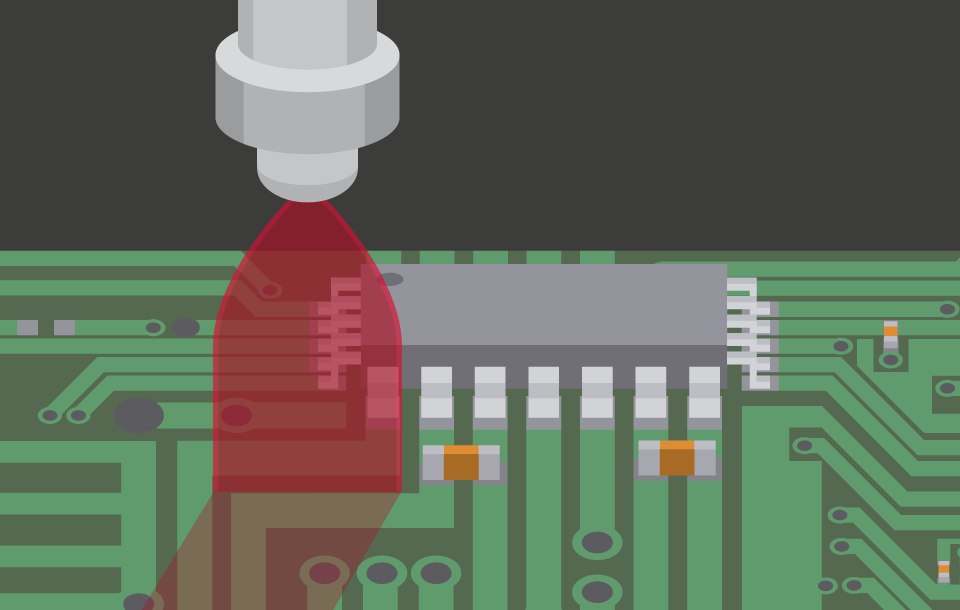

Film coat valves for uniform coating including accurate working edges

Film coat valves are ideal for high-speed coating – for uniform, broad coatings with accurate working edges without splashing.

- Film coating through product design with low flow rate.

- Broad film coating with special nozzle.

- Numeric management available with integrated micrometer.

- Electropneumatic valve technology for fast, precise opening and closing.

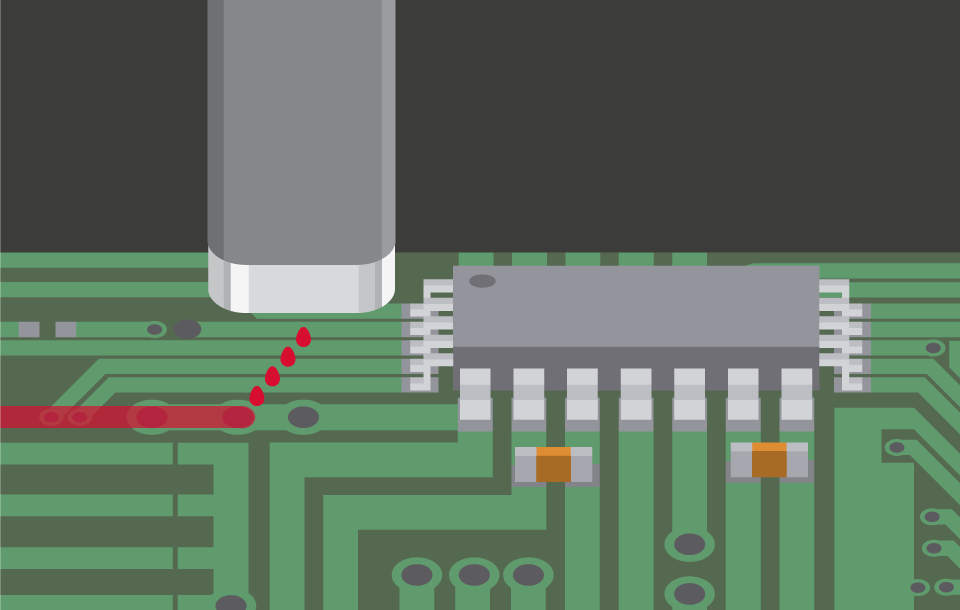

Ideal for dispensing micro volumes or materials containing UV or fillers.

Dosing valves (with time-pressure control) are ideal for sealing beads and drop dosing as well as micro-volume dispensing of UV materials or materials containing fillers.

- Excellent liquid control.

- Membrane structure reduces bubble inclusion and prevents liquid filtration in the gliding zone.

- Ideal for automatic machines: rectangular shape, compact size, very lightweight.

- Models available with large flow rate up to three-fold.

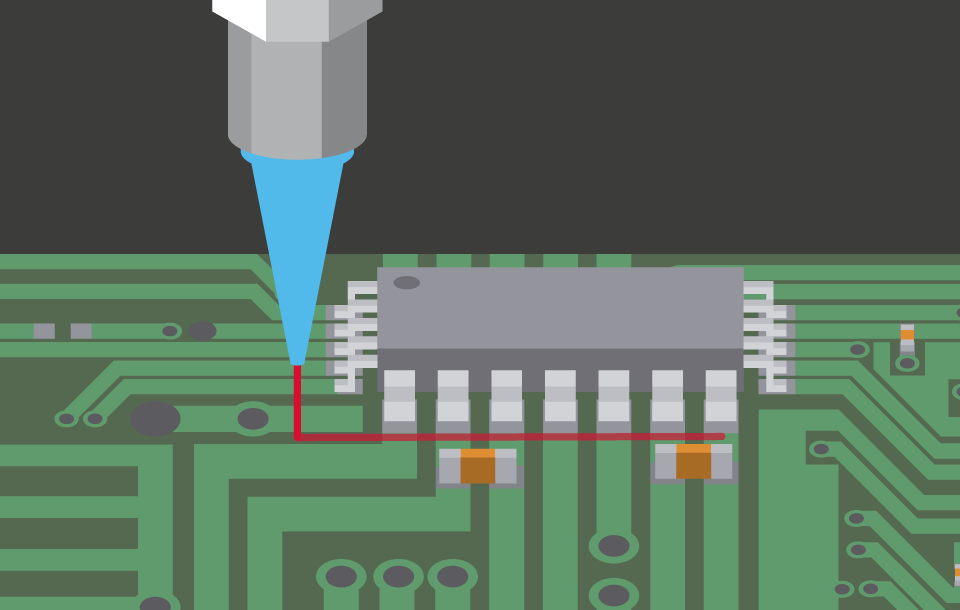

Jet valves for high speed dosing of medium- to high-viscosity materials with extremely high reproducibility

Alpha 6 with jet valve technology offers high-precision, contact-free, high-speed dispensing with extremely high reproducibility

- Valve temperature control and interchangeable dosing chambers and needles.

- Ideal for dosing fluxing agent, SMT adhesive, underfill, coating, sealant adhesives, heat conductive paste, conductive adhesive, silver paste, soldering paste, grease, oil, lubricants, seals, adhesives and curing agents.

- Including mixing devices for dosing emulsions.

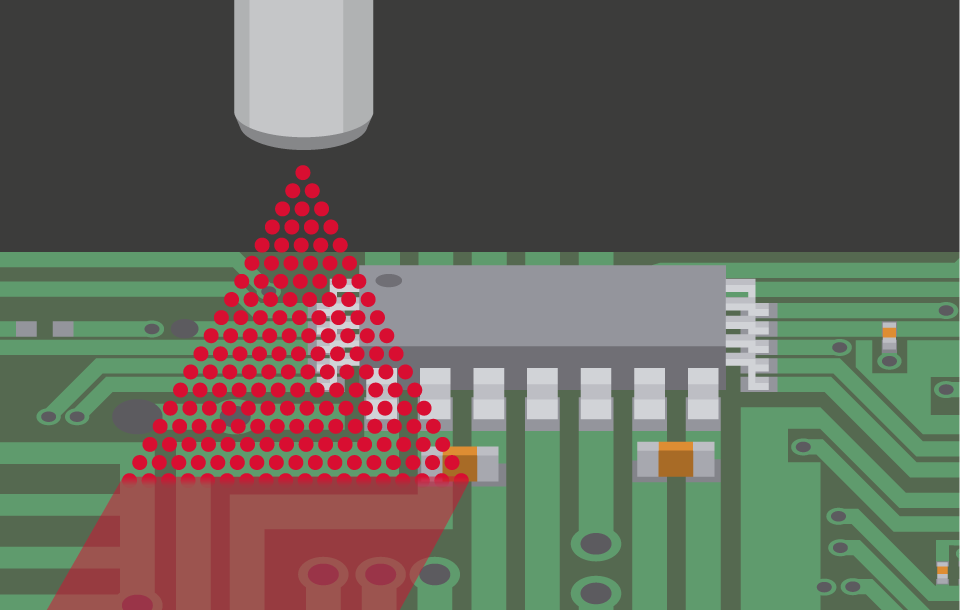

Spray valves for universal, extensive coating of thin foils that can be applied to workpieces in all shapes.

A spray valve permits universal conformal coating regardless of viscosity of thin foils with uniform film thickness, with top coating quality.

- Exclusive nozzle for uniform film thickness.

- Low-pressure atomisation to prevent overspray.

- Supports several heads.

- Complete system installation.

Valve accessories

Products for precision dosing: cartridges, nozzles, needles, accessories

Whether cartridges, nozzles, needles or accessories, our assortment stands out with extremely high precision, quality and reliability. Developed and produced with unique know-how in dosing technology.

Clear cartridges, cartridges with UV blocker, adapter tube with stopper, plungers, versatile metal needles, plastic needles with double threaded screw, conical double threaded nozzles and dosing brushes and much more besides:

WERNER WIRTH offers all you need for precision dosing.

The cartridges in our range guarantee extremely easy passage and smooth plunger movement without any jolting. The result is precise dosing with enhanced quality and efficiency. Whether clear cartridges, cartridges with UV blocker, adapter tube (with stopper) or plungers for complete emptying, WERNER WIRTH offers dosing technology of the very best.

The dosing nozzles and needles in our range guarantee high-precision dosing. State-of-the-art computers were used to develop their unique design. They are produced in highest quality with sophisticated processing technology. Whether versatile metal needles, plastic needles with double threaded screw, conical double threaded nozzles or dosing brushes for large surfaces.

Here you can find the product data sheet for our valve accessories as a PDF for downloading. Please do not hesitate to contact us if you have any further questions.

We are at your service!

Do you have any questions about Conformal Coating, or would you like to exchange ideas without obligation? Let’s talk together to see how we can support you.

We look forward to engaging with you.

Feel free to call me directly: +49 40 75 24 91-25

Yours sincerely,

Jörg Buch